Mixed-Integer linear programming

| Class date(s): | 25 March 2015 | ||||

| |||||

| |||||

| |||||

| |||||

| |||||

Resources

Scroll down, if necessary, to see the resources.

| Date | Class number | Topic | Slides/handouts for class | Video file | References and Notes |

|---|---|---|---|---|---|

| 25 March | 11B |

|

Video |

See the GAMS codes below | |

| 30 March | 12A |

More problems that can be solved with integer variables

|

Video |

See the GAMS codes below | |

| 01 April | 12B |

The branch and bound procedure to solve integer problems |

Video |

See code below to solve the original problem, and then the relaxed problem. See another example problem below (with solution). | |

| 06 April | 13A |

Working towards understanding schedule problems in engineering

|

Video |

See code below for the simple scheduling problem (3 products on 1 unit). | |

| 08 April | 13B |

Scheduling problems Course wrap-up |

Video |

|

Solving a basic ILP

free variable income "total income";

positive variables x1, x2;

binary variable delta "use ingredient x3 or not at all";

EQUATIONS

obj "maximize income",

blend "blending constraint";

obj.. income =E= 18*x1 - 3*x2 - 9*(20*delta);

blend.. 2*x1 + x2 + 7*(20*delta) =L= 150;

x1.up = 25;

x2.up = 30;

model recipe /all/;

SOLVE recipe using MIP maximizing income;

Solving the knapsack problem

free variable value "total value";

sets j "item j" /1*5/;

binary variables x(j) "whether to include item in the knapsack";

parameter v(j) "value of object j"

/1 4,

2 2,

3 10,

4 1,

5 2/;

parameter w(j) "weight of object j"

/1 12,

2 1,

3 4,

4 1,

5 2/;

EQUATIONS

obj "maximize value",

weight "weight constraint";

obj.. value =e= sum(j, v(j)*x(j));

weight.. sum(j, w(j)*x(j)) =L= 15;

model knapsack /all/;

solve knapsack using mip maximizing value;

Solving the knapsack problem for selecting amount projects, with constraints

free variable value "total value";

sets j "item j" /1*5/;

binary variables x(j) "whether to include item in the project";

parameter v(j) "value of object j"

/1 50,

2 72,

3 25,

4 41,

5 17/;

parameter w(j) "cost of object j"

/1 8,

2 21,

3 15,

4 10,

5 7/;

EQUATIONS

obj "maximize value",

weight "weight constraint",

me1v2 "1 and 2 are mutually exclusive",

me1v3v5 "1, 3 and 5 are mutually exclusive",

d4v3 "4 depends on 3";

obj.. value =e= sum(j, v(j)*x(j));

weight.. sum(j, w(j)*x(j)) =L= 35;

me1v2.. x('1') + x('2') =L= 1;

me1v3v5.. x('1') + x('3') + x('5') =L= 1;

d4v3.. x('4') =L= x('3');

model projects /all/;

solve projects using mip maximizing value;

Binary problem relaxation

This is the problem we looked at in class for the generators.

Notice that the only differences are:

- the binary variables become positive variables, thepr

- the problem is solved as an LP not an MIP

- the constraints for .LO and .UP are added, where required, depending on the partial solution solved

| Original problem solved in class | Relaxed problem solved in class |

|---|---|

free variable cost "total cost";

sets j "item j" /1*4/;

binary variables x(j) "whether to use generator";

parameter c(j) "cost of using generator j"

/1 7,

2 12,

3 5,

4 14/;

parameter p(j) "power of generator j"

/1 300,

2 600,

3 500,

4 1600/;

EQUATIONS

obj "cost",

power_constraint;

obj.. cost =e= sum(j, c(j)*x(j));

power_constraint.. sum(j, p(j)*x(j)) =G= 700;

MODEL purchase /all/;

SOLVE purchase using MIP minimizing cost;

|

free variable cost "total cost";

sets j "item j" /1*4/;

positive variables x(j) "whether to use generator";

parameter c(j) "cost of using generator j"

/1 7,

2 12,

3 5,

4 14/;

parameter p(j) "power of generator j"

/1 300,

2 600,

3 500,

4 1600/;

EQUATIONS

obj "cost",

power_constraint;

obj.. cost =e= sum(j, c(j)*x(j));

power_constraint.. sum(j, p(j)*x(j)) =G= 700;

* Solve the problem for the partial solution: (#, 0, #, 1)

x.LO('1')=0;

x.UP('1')=1;

x.LO('2')=0;

x.UP('2')=0;

x.LO('3')=0;

x.UP('3')=1;

x.LO('4')=1;

x.UP('4')=1;

MODEL purchase /all/;

SOLVE purchase using LP minimizing cost;

|

Example problem to practice

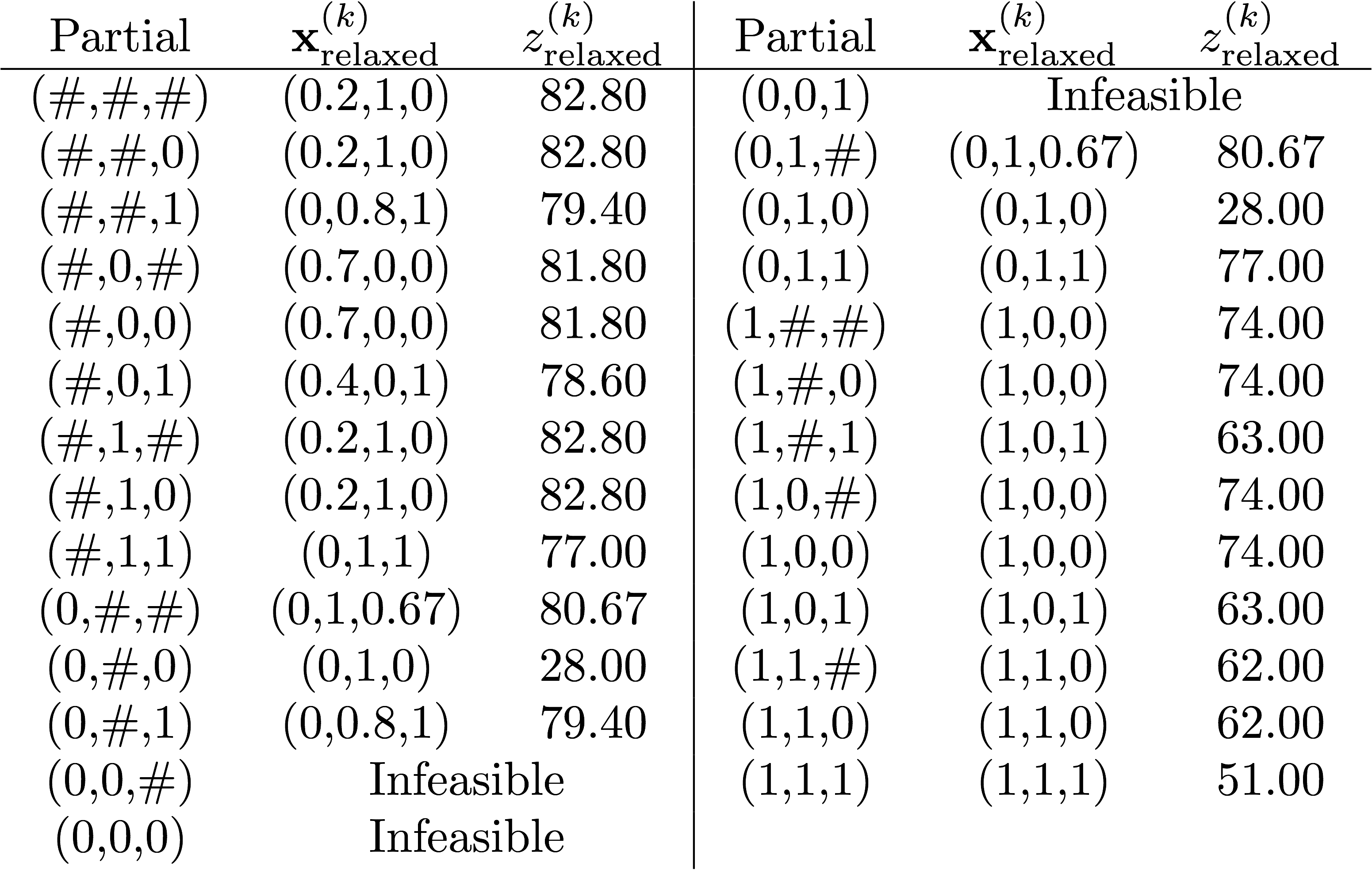

The objective is to maximize the objective function value, \(z\). The table or partial solutions is provided below. The only constraints are that all the 3 search variables must be binary (0 or 1). The "relaxed" refers to the relaxed problem solution.

Use the depth-first search method, and when branching, choose the branch with \(x_i = 0\) before the \(x_i=1\) branch.

If you do this, your nodes will have the following solution order:

Node 0 \((z=82.80)\)

Node 1 \((z=80.67)\)

Node 2 \((z=28.00)\) [incumbent]

Node 3 \((z=79.4)\)

Node 4 \((z=\text{Infeasible})\)

Node 5 \((z=77.00)\) [incumbent; turns out this is the eventual optimum]

Node 6 \((z=74.00)\)

[The end: can you prove why?]

Simple schedule: one unit, 3 products

This example was covered in class 13A:

set j "jobs" /1*3/;

alias (j,jp);

parameter p(j) "process time of j"

/ 1 15, 2 6, 3 9/;

scalar M "bigM";

M = sum(j, p(j));

free variable MeanComp "Mean completion time";

positive variables x(j) "Start time of job j";

binary variables y(j,jp) "Disjunctive variable for j and jp";

EQUATIONS

MeanCeqn "Mean completion time",

Disj1(j,jp) "Disjunctive part 1",

Disj2(j,jp) "Disjunctive part 2";

MeanCeqn.. MeanComp =E= sum(j, x(j)+p(j) ) / card(j);

Disj1(j,jp)$(ord(j) lt ord(jp)).. x(j) + p(j) =L= x(jp) + M*(1-y(j,jp));

Disj2(j,jp)$(ord(j) lt ord(jp)).. x(jp)+ p(jp) =L= x(j) + M*y(j,jp);

MODEL simplesched /all/;

SOLVE simplesched using MIP minimizing MeanComp;

Scheduling 3 products on 4 units

This example was covered in class 13B:

* Based on: https://comp.uark.edu/~rrardin/oorbook/software/gams/custommw.gms

set j "Products" /A*C/,

k "Units" /1*4/;

alias (j,jp);

alias (k,kp);

set succ(j,k,kp) "Product j successor pairs"

/A.1.2, A.2.3, A.3.4,

B.3.4,

C.3.2, C.2.4/;

TABLE p(j,k) "Process time of product j on unit k"

1 2 3 4

A 1 5 4.0 1.5

B 0 0 4.5 1.0

C 0 3 5.0 1.5;

scalar M "bigM";

M = sum((j,k), p(j,k));

FREE variable

AverageC "Average completion time";

POSITIVE variables x(j,k) "Start time of job (product) j on unit k: j.k";

BINARY variables y(j,jp,k) "Disjunctive variable for j and jp on k";

EQUATIONS

avgComplete "Average completeness",

pred(j,k,kp) "Precedence within jobs",

disj1(j,jp,k) "Disjunctive part 1 for j and jp on k",

disj2(j,jp,k) "Disjunctive part 2 for j and jp on k";

avgComplete.. AverageC =E= sum((j,k), x(j,k)+p(j,k) );

* These are the precedence constraints

pred(j,k,kp)$succ(j,k,kp).. x(j,k) + p(j,k) =L= x(j,kp);

disj1(j,jp,k)$(ord(j) lt ord(jp) and p(j,k) gt 0 and p(jp,k) gt 0)..

x(j,k) + p(j,k) =L= x(jp,k) + M*(1-y(j,jp,k));

disj2(j,jp,k)$(ord(j) lt ord(jp) and p(j,k) gt 0 and p(jp,k) gt 0)..

x(jp,k) + p(jp,k) =L= x(j,k) + M*y(j,jp,k);

MODEL Jobshop /all/;

option mip = mosek;

SOLVE Jobshop USING MIP minimizing AverageC;