Difference between revisions of "Liquid-liquid extraction - 2014"

Kevin Dunn (talk | contribs) |

Kevin Dunn (talk | contribs) |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

__NOTOC__ | __NOTOC__ | ||

{{ | {{ClassSidebarYouTube | ||

| date = 29 October 2014 | | date = 29 October 2014 | ||

| dates_alt_text = | | dates_alt_text = | ||

| vimeoID1 = | | vimeoID1 = N3CsY6oANhw | ||

| vimeoID2 = | | vimeoID2 = hz1HaKJd5pU | ||

| vimeoID3 = | | vimeoID3 = gX7sKIes0Zo | ||

| vimeoID4 = | | vimeoID4 = v-mNuDk-p2s | ||

| vimeoID5 = | | vimeoID5 = 6rChTv_D5sU | ||

| vimeoID6 = | | vimeoID6 = PkOeNkUbVxw | ||

| vimeoID7 = | | vimeoID7 = | ||

| vimeoID8 = | | vimeoID8 = | ||

| Line 29: | Line 29: | ||

| video_notes3 = | | video_notes3 = | ||

| video_download_link4_MP4 = http://learnche.mcmaster.ca/media/2014-4M3-Class-10C.mp4 | | video_download_link4_MP4 = http://learnche.mcmaster.ca/media/2014-4M3-Class-10C.mp4 | ||

| video_download_link4_MP4_size = M | | video_download_link4_MP4_size = 586 M | ||

| video_notes4 = | | video_notes4 = | ||

| video_download_link5_MP4 = | | video_download_link5_MP4 = http://learnche.mcmaster.ca/media/2014-4M3-Class-11A.mp4 | ||

| video_download_link5_MP4_size = M | | video_download_link5_MP4_size = 797 M | ||

| video_notes5 = | | video_notes5 = | ||

| video_download_link6_MP4 = | | video_download_link6_MP4 = http://learnche.mcmaster.ca/media/2014-4M3-Class-11B.mp4 | ||

| video_download_link6_MP4_size = M | | video_download_link6_MP4_size = 357 M | ||

| video_notes6 = | | video_notes6 = | ||

| video_download_link7_MP4 = | | video_download_link7_MP4 = | ||

| Line 52: | Line 52: | ||

* Schweitzer, "Handbook of Separation Techniques for Chemical Engineers", Chapter 1.9, [http://catalogue.mcmaster.ca/catalogue/Record/1156427 McMaster library] | * Schweitzer, "Handbook of Separation Techniques for Chemical Engineers", Chapter 1.9, [http://catalogue.mcmaster.ca/catalogue/Record/1156427 McMaster library] | ||

* Seader, Henley and Roper, "Separation Process Principles", Chapter 8 in 2nd and 3rd edition [http://catalogue.mcmaster.ca/catalogue/Record/1270236 McMaster Libraries] (reserve) | * Seader, Henley and Roper, "Separation Process Principles", Chapter 8 in 2nd and 3rd edition [http://catalogue.mcmaster.ca/catalogue/Record/1270236 McMaster Libraries] (reserve) | ||

== Resources == | |||

''Scroll down, if necessary, to see the resources.'' | |||

{| class="wikitable" style="text-align: center;" | {| class="wikitable" style="text-align: center;" | ||

| Line 127: | Line 130: | ||

# A general article on [http://learnche.mcmaster.ca/media/mcmaster/Reissinger-Schroter--Liquid-liquid-extractors.pdf liquid liquid extractors]. | # A general article on [http://learnche.mcmaster.ca/media/mcmaster/Reissinger-Schroter--Liquid-liquid-extractors.pdf liquid liquid extractors]. | ||

# An interesting [http://learnche.mcmaster.ca/media/mcmaster/Moore--Using-principles-of-inherent-safety-in-design-of-hydrometallurgical-solvent-extraction-plants.pdf reading on safety in liquid-liquid extraction plants]: a further reason for counter-current operations to minimize solvent use. | # An interesting [http://learnche.mcmaster.ca/media/mcmaster/Moore--Using-principles-of-inherent-safety-in-design-of-hydrometallurgical-solvent-extraction-plants.pdf reading on safety in liquid-liquid extraction plants]: a further reason for counter-current operations to minimize solvent use. | ||

|- | |||

| 12 November | |||

| 11B | |||

| align="left" colspan="1"| | |||

Liquid liquid extraction example calculations | |||

| align="left" colspan="1"| | |||

[[Media:2014-4M3-Liquid-Liquid-Extraction.pdf|Slides]] | |||

| [http://learnche.mcmaster.ca/media/2014-4M3-Class-11B.mp4 Video] | |||

| [http://learnche.mcmaster.ca/media/2014-4M3-Class-11B.mp3 Audio] | |||

|align="left" colspan="1"| | |||

|} | |} | ||

== Exercise == | == Exercise == | ||

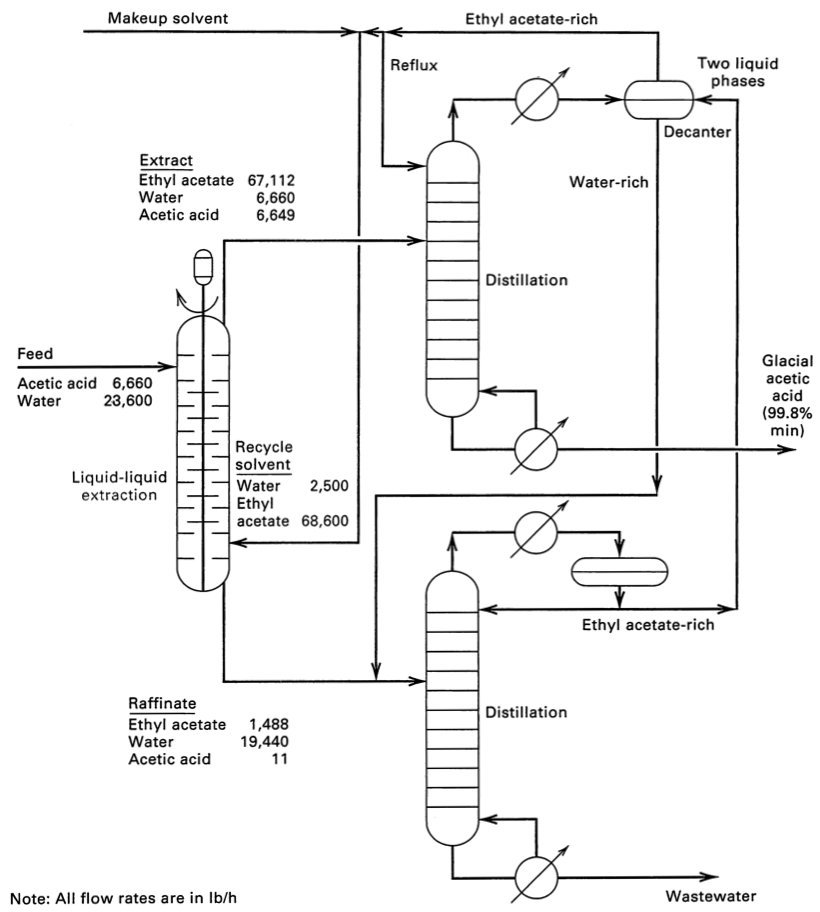

[[Image:Adsorption-example-from-VLE-raw-data.png| | A stream of acetic acid and water (also called diluent) is being fed in a counter current manner at 1000 kg/hour, in order to extract the acetic acid. The feed composition is 30 wt% acetic acid, and 70 wt% water. | ||

The solvent is 99% pure IPE (isopropyl ether), and contains 1% acetic acid, at an inlet flow of 2500 kg/hour. | |||

We desire the exiting raffinate stream to contain 5 wt% acetic acid. | |||

# Find the number of equilibrium stages to achieve this separation (show all calculations). | |||

# Calculate the exiting raffinate flow, and the exiting extract flow rate. | |||

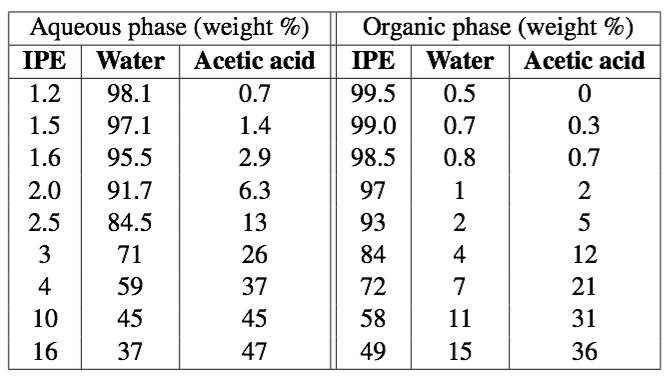

Unfortunately, we don't have the equilibrium data, however, various samples of the 3 species were made, mixed, and when they came to equilibrium they were found to have the following compositions (each row gives the aqueous and organic phase compositions): | |||

[[Image:Adsorption-example-from-VLE-raw-data.png|500px]] | |||

Feel free to download and use [http://upload.wikimedia.org/wikipedia/commons/8/81/Ternary_plot_1.png this empty ternary diagram]. | |||

See [http://www.youtube.com/watch?v=N7MIH0_ELO0 this YouTube video] for the full solution.. | See [http://www.youtube.com/watch?v=N7MIH0_ELO0 this YouTube video] for the full solution.. | ||

Latest revision as of 08:57, 6 January 2017

| Class date(s): | 29 October 2014 | ||||

| |||||

| |||||

| |||||

| |||||

| |||||

| |||||

References

Please use these references to read ahead, or for extra background reading on liquid-liquid extraction. In alphabetical order:

- Ghosh, R. "Principles of Bioseparations Engineering", Chapter 7, McMaster (reserve)

- Geankoplis, C.J. "Transport Processes and Separation Process Principles", Chapter 12 in 3rd and 4th edition, McMaster Libraries (reserve)

- Perry's Chemical Engineers' Handbook, Chapter 15, Direct link (McMaster subscription)

- Richardson and Harker, "Chemical Engineering, Volume 2", 5th edition, Chapter 13 ebook

- Schweitzer, "Handbook of Separation Techniques for Chemical Engineers", Chapter 1.9, McMaster library

- Seader, Henley and Roper, "Separation Process Principles", Chapter 8 in 2nd and 3rd edition McMaster Libraries (reserve)

Resources

Scroll down, if necessary, to see the resources.

| Date | Class number | Topic | Slides for class | Video and audio files | References and Notes | |

|---|---|---|---|---|---|---|

| 29 October | 09B |

Liquid liquid extraction overview |

Video | Audio |

A comprehensive article on liquid-liquid extraction which describes the various units available. | |

| 04 November | 10A |

Liquid liquid extraction theory and calculations |

Video | Audio |

[reference: Seader et al., p300] | |

| 05 November | 10B |

Liquid liquid extraction example calculations |

Video | Audio |

| |

| 07 November | 10C |

Liquid liquid extraction example calculations |

Video | Audio |

Web links shown in the class: | |

| 11 November | 11A |

Liquid liquid extraction example calculations |

Video | Audio |

These readings seem old, but they are still relevant. For example, the same principles are used in modern bioseparations.

| |

| 12 November | 11B |

Liquid liquid extraction example calculations |

Video | Audio | ||

Exercise

A stream of acetic acid and water (also called diluent) is being fed in a counter current manner at 1000 kg/hour, in order to extract the acetic acid. The feed composition is 30 wt% acetic acid, and 70 wt% water.

The solvent is 99% pure IPE (isopropyl ether), and contains 1% acetic acid, at an inlet flow of 2500 kg/hour.

We desire the exiting raffinate stream to contain 5 wt% acetic acid.

- Find the number of equilibrium stages to achieve this separation (show all calculations).

- Calculate the exiting raffinate flow, and the exiting extract flow rate.

Unfortunately, we don't have the equilibrium data, however, various samples of the 3 species were made, mixed, and when they came to equilibrium they were found to have the following compositions (each row gives the aqueous and organic phase compositions):

Feel free to download and use this empty ternary diagram.

See this YouTube video for the full solution..