Difference between revisions of "Liquid-liquid extraction - 2012"

Jump to navigation

Jump to search

Kevin Dunn (talk | contribs) |

Kevin Dunn (talk | contribs) |

||

| Line 91: | Line 91: | ||

:# Calculate the flow and composition of the extract and raffinate from: | :# Calculate the flow and composition of the extract and raffinate from: | ||

:#* 1st co-current stage, using a pure solvent flow of 50 kg/hr. | :#* 1st co-current stage, using a pure solvent flow of 50 kg/hr. | ||

:# | :#* 2nd co-current stage, with an additional solvent flow of 50 kg/hr. | ||

:# For the overall 2-stage system, find the: | :# For the overall 2-stage system, find the: | ||

:#* overall recovery | :#* overall recovery | ||

Revision as of 23:17, 1 November 2012

| Class date(s): | 23 to 26 October 2012 | ||||

| |||||

| |||||

| |||||

| |||||

| |||||

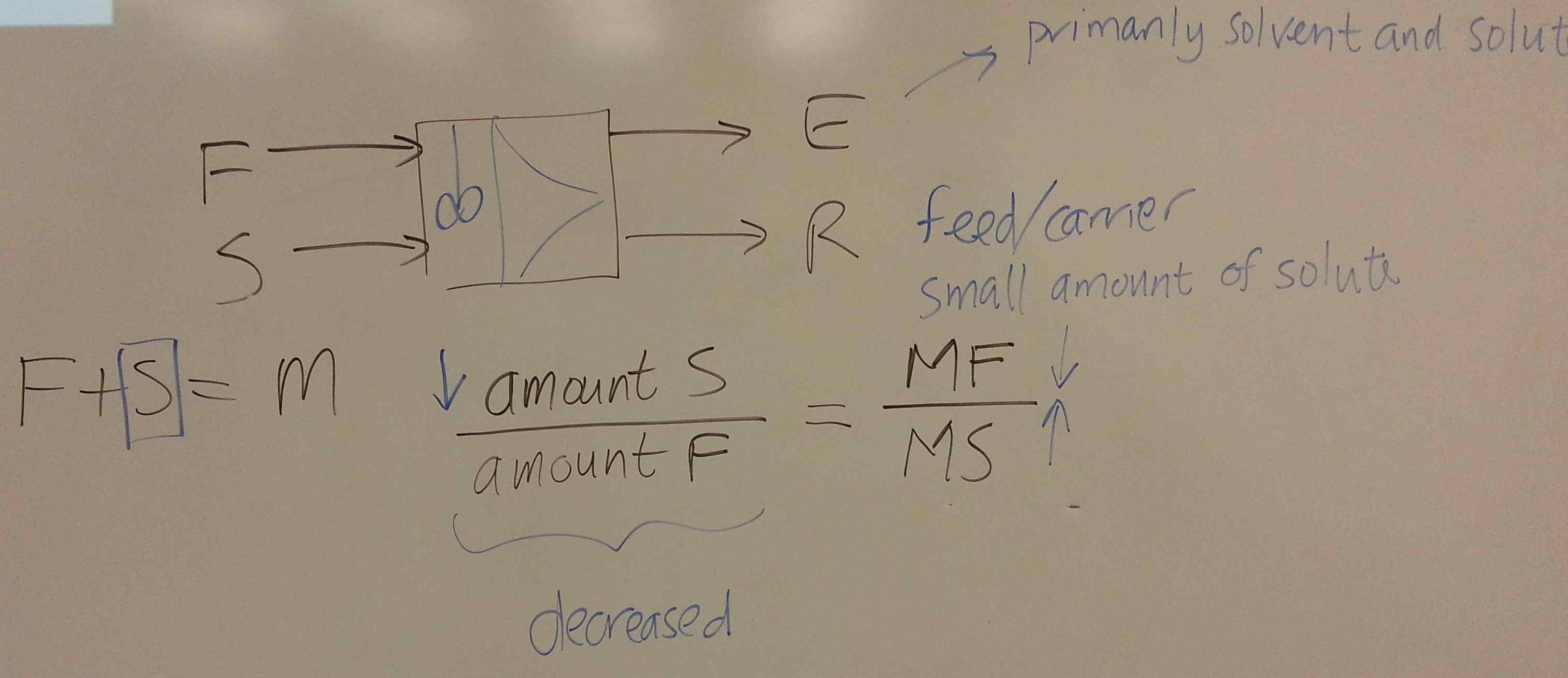

We start this section by looking at liquid-liquid extraction.

References

Please use these references to read ahead, or for extra background reading on liquid-liquid extraction. In alphabetical order:

- Ghosh, R. "Principles of Bioseparations Engineering", Chapter 7, McMaster (reserve)

- Geankoplis, C.J. "Transport Processes and Separation Process Principles", Chapter 12 in 3rd and 4th edition, McMaster Libraries (reserve)

- Perry's Chemical Engineers' Handbook, Chapter 15, Direct link (McMaster subscription)

- Richardson and Harker, "Chemical Engineering, Volume 2", 5th edition, Chapter 13 ebook

- Schweitzer, "Handbook of Separation Techniques for Chemical Engineers", Chapter 1.9, McMaster library

- Seader, Henley and Roper, "Separation Process Principles", Chapter 8 in 2nd and 3rd edition McMaster Libraries (reserve)

Interesting applications / Enrichment materials

- An article on liquid-liquid extraction which describes the various units available.

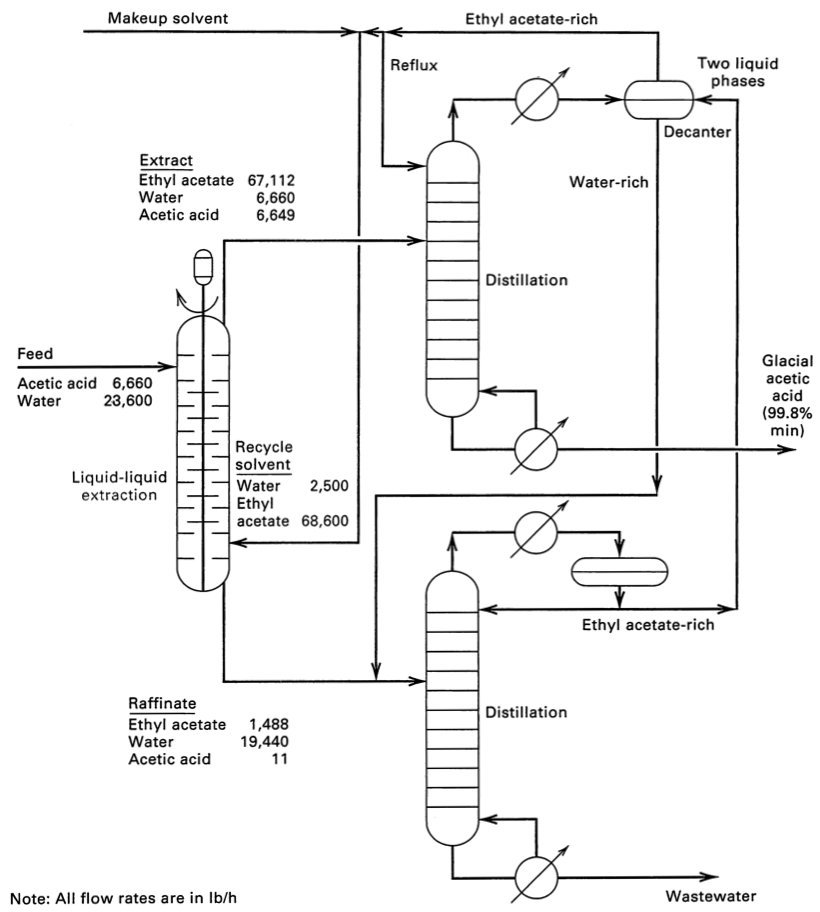

- The flowsheet for separating acetic acid from water using ethyl acetate solvent. This flowsheet has the mass flow rates, to help contrast it to distillation.

Week 8

23 Oct 2012 (08A)

- Slides for class

- Audio and video recording of the class.

25 Oct 2012 (08B)

- Slides for class

- Audio and video recording of the class.

26 Oct 2012 (08C)

- Slides for class

- Audio and video recording of the class.

- Three photos of the board during class

Week 9

30 Oct 2012 (09A)

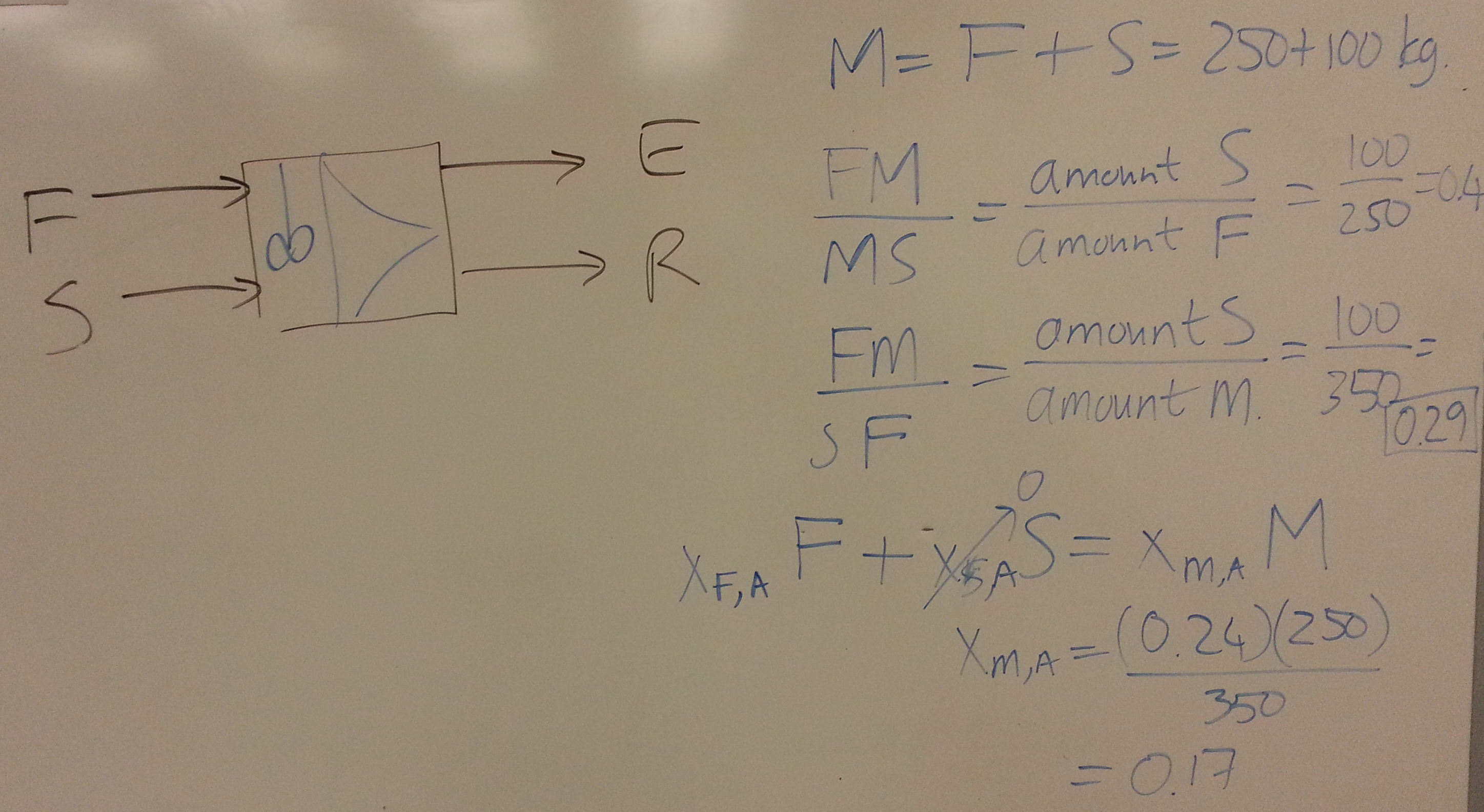

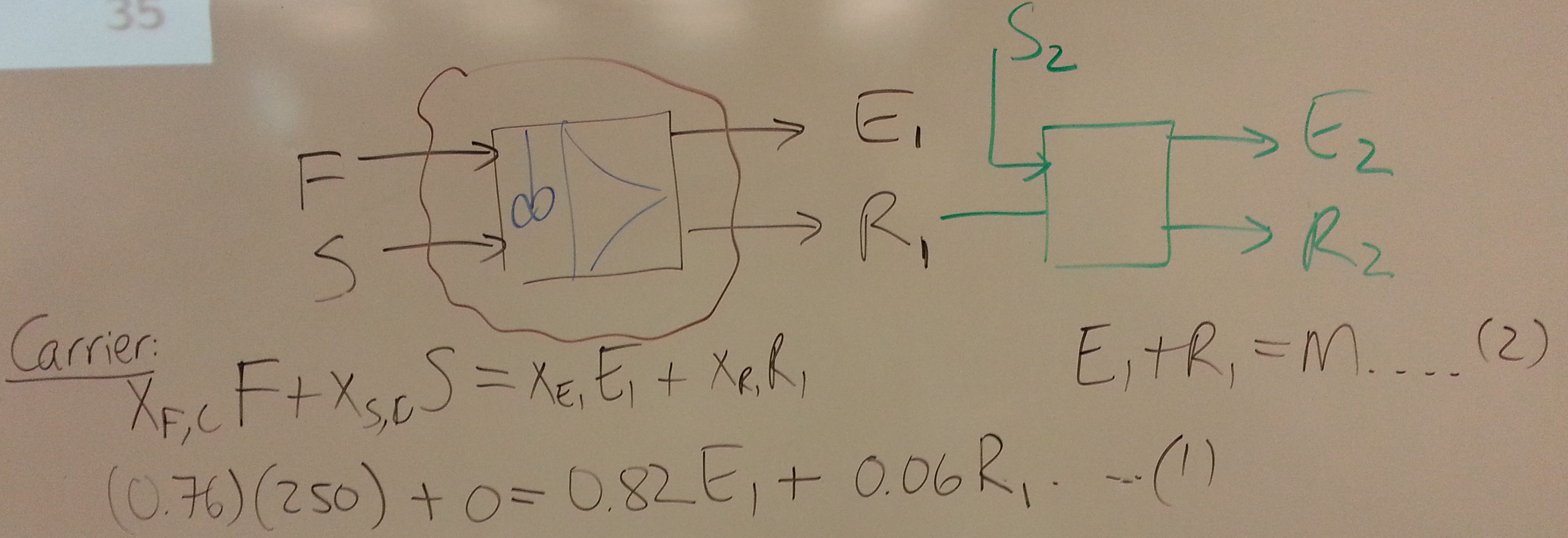

We will consider single and multiple co-current extraction.

- Slides for class

- Audio and video recording of the class.

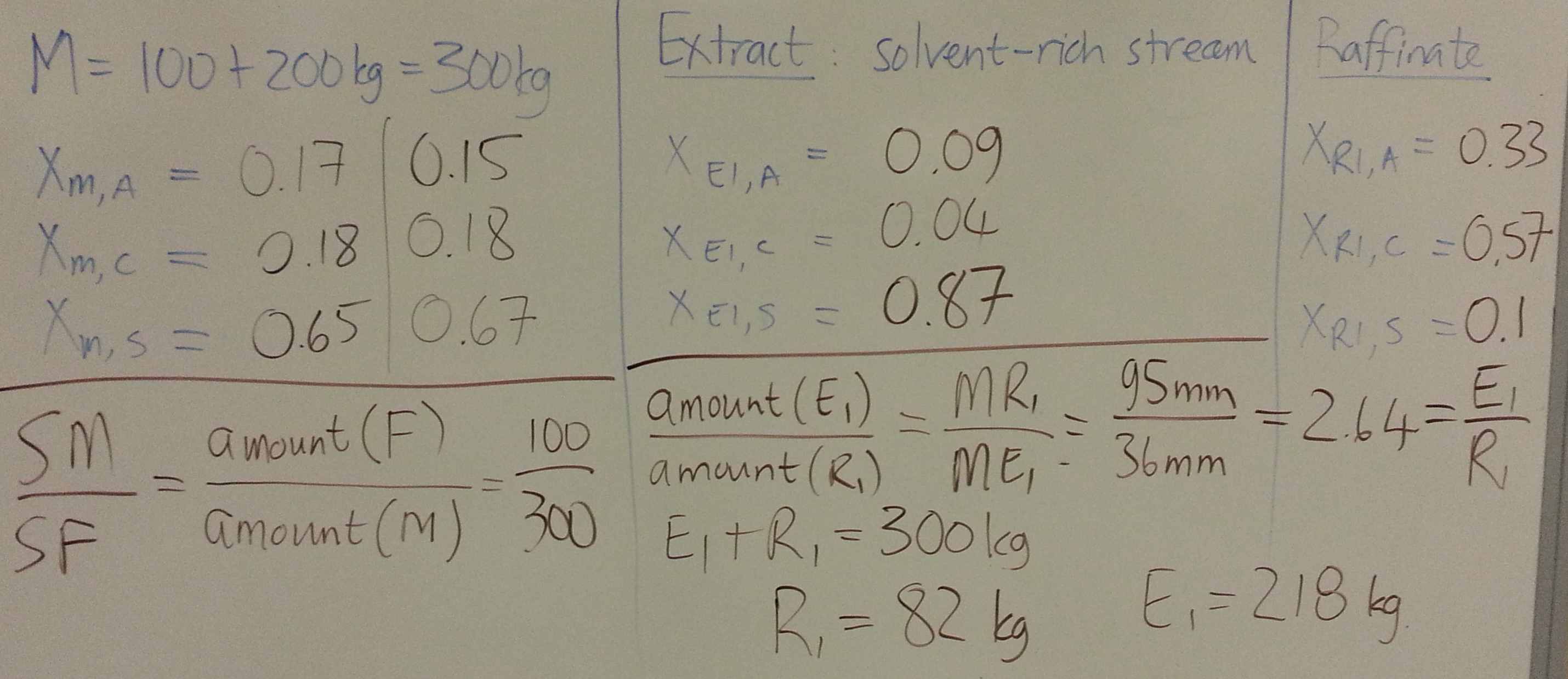

- Photo of the board during class

31 Oct 2012 (09B)

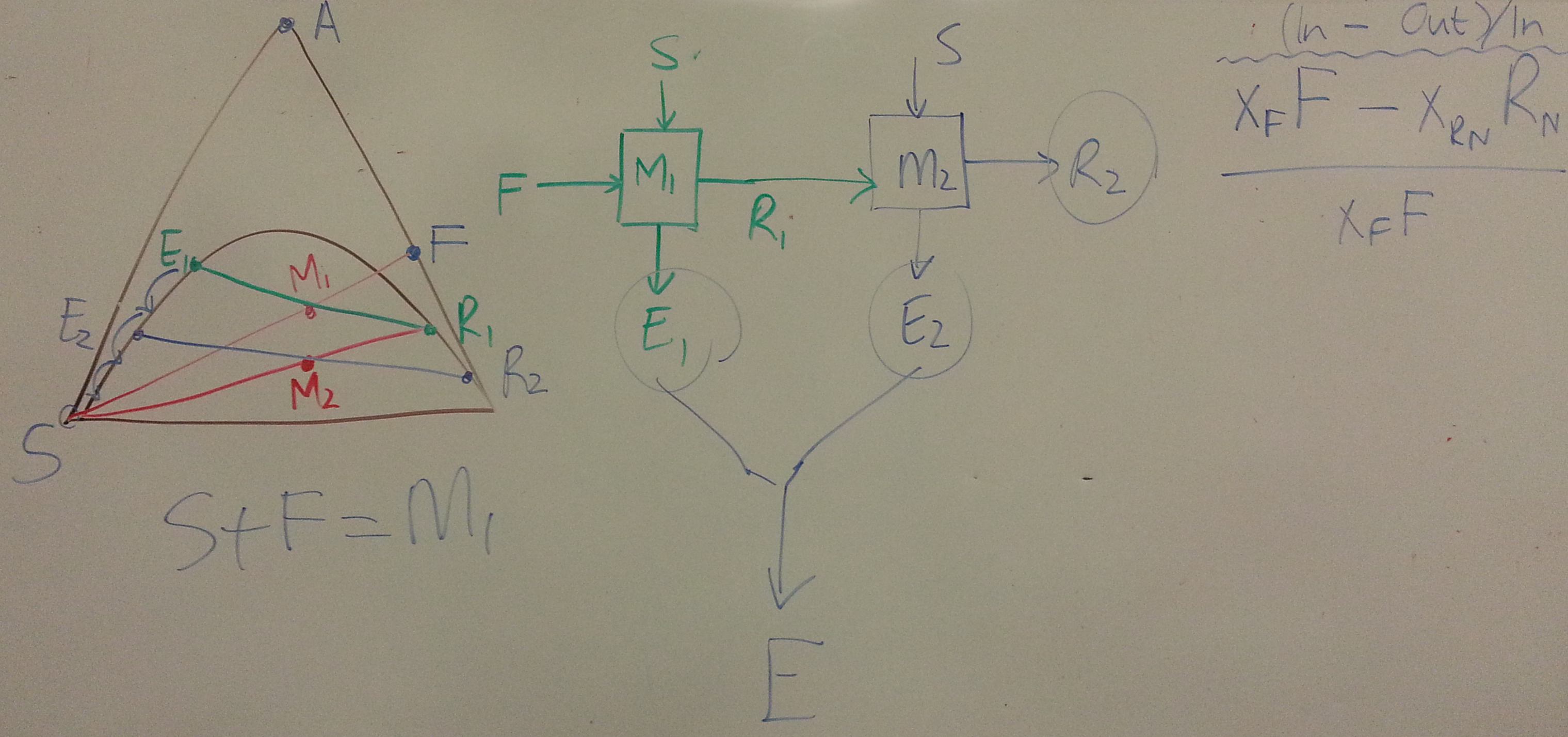

We should be able to wrap up the section by studying counter-current liquid-liquid extraction.

- Slides for class (slides 42 to 59). Please print slides 48 to 54 on large, single pages, to assist your learning.

- Audio and video recording of the class.

- Photo of the board during class

01 Nov 2012 (09C)

- There will be no formal teaching in class today. You can ask questions about assignment 4, and there will be a tutorial question from assignment 5.

- Consider a system for which you have been given the ternary diagram (see slides, p 58).

- Calculate the flow and composition of the extract and raffinate from:

- 1st co-current stage, using a pure solvent flow of 50 kg/hr.

- 2nd co-current stage, with an additional solvent flow of 50 kg/hr.

- For the overall 2-stage system, find the:

- overall recovery

- overall concentration of combined extract streams

- Calculate the flow and composition of the extract and raffinate from:

- The next objective is to have a counter-current system so the raffinate leaving in the

- What is the maximum allowable solvent flow?

- Explain whether it's possible to achieve an extract stream of

- Show the construction on the ternary diagram for the number of equilibrium stages to achieve

- Plot on the same axes the concentrations in the extract and raffinate streams.